Quadrotor

- May 14th, 2010

- Write comment

I’ve wanted to build a quadrotor for a long time now. Not only is it an interesting controls project, but it can go places that few other air vehicles can. It has the potential to carry substantial payloads opening the door for some powerful on-board computing. In starting this project I decided to start from scratch with everything because my goal is not to simply have a quadrotor (anyone with enough money can do that). I wanted to go through the exercise of developing a substantial control system and code base. When the project gets further along I will likely switch to an open protocol for my data transfer, but the all important control code will always be my own.

The project started about one year ago with a slightly different intent. The goal was to design a quadrotor frame that would be statically stable and damped enough that the pilot could fly it. The idea was that a large weight below the plane of the rotors would act like a pendulum which would right the vehicle. After building the vehicle I tested it by suspending the frame so that it was free to rotate. Because the point at which it was suspended was above the CG (thanks to the 2 pound weight on the bottom) the vehicle appeared to be statically stable.

However, even with this crutch, the vehicle was still impossible to keep level due to the dynamic instability. In the end the concept was abandoned and the parts for an inertial measurement unit were ordered. The sensors included a 3-axis accelerometer and three single axis gyros. The sensors were carefully assembled orthographically to each other. Unfortunately I found out the hard way that the analog pins default to outputing, thus my 5 volt Sanguino fried all of my sensors. This accident ended the project for that summer. It wasn’t until January of this year that the advent of Sparkfun’s 9 DOF that the project was resumed.

The original frame was put to use and was rechristened the Cakecopter since all of the electronics were housed in a Harris Teeter cake tin. Most of the core development occured over the course of about a week and a half. The vehicle reached the point where it was able to do short hovers (~5 seconds) within a small area. Sadly during one such test the vehicle had a hard landing in such a way that it broke both of the counterclockwise (CCW) rotating props. This wouldn’t have been a problem except that the only props I have ever broken on this project have been CCW, so despite having ordered three full sets of blades I was out of replacements.

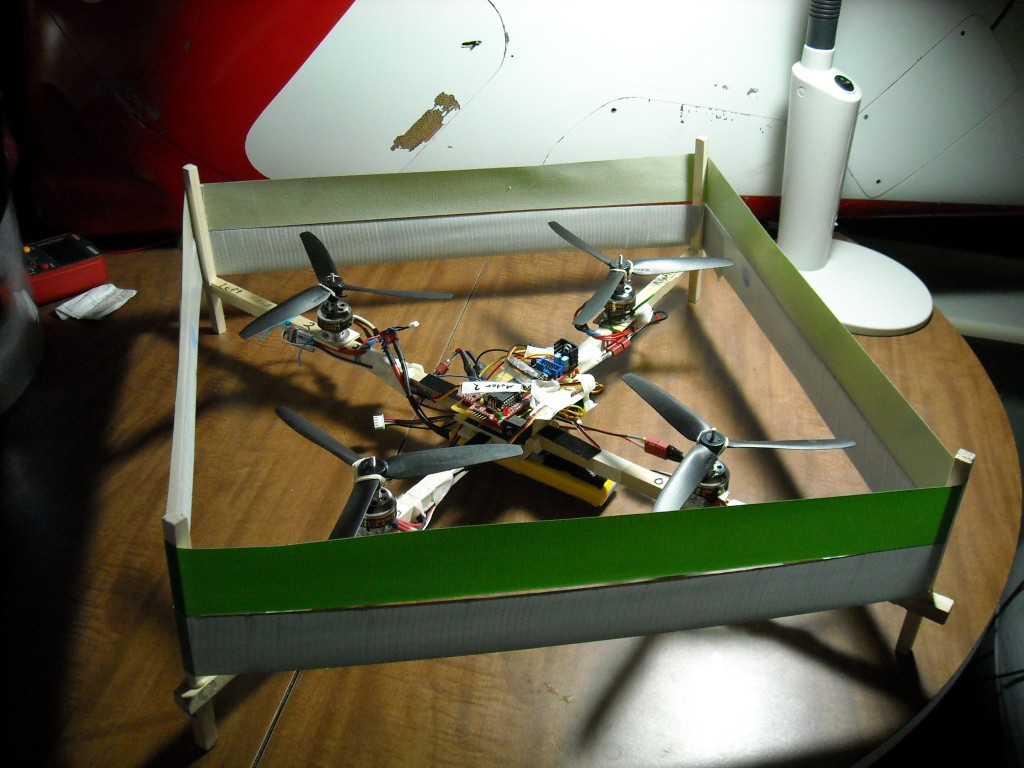

Having anticipated this challenge during the early flight tests I had order four sets of small tri-bladed props as a backup. Unfortunately, the new props did not generate nearly as much thrust as the single bladed props, so the frame had to be redesigned to reduce weight. The new frame (unnamed as of yet) is lighter, more compact, and allows for a full enclosure for the blades. The current configuration uses a duct tape band to keep things away from the prop. I did cut a soft foam block to serve as protection (as well as make the vehicle look awesome), but it ended up being far to heavy for the vehicle. The foam has since been re-purposed as the body for the Broughton-Moving-Monster.

Retuning the PID gains for this new body took much less time than for the Cakecopter. During the last flight test the vehicle showed static and dynamic stability, but a low battery prevented enough thrust for lift-off. When a fresh battery was added one of the motor controllers died. I am now awaiting the replacement part which should arrive sometime in the next few days.