Since the beginning of the semester we have made significant strides forward in building our senior design aircraft. This post will focus on the fabrication of the fuselage plug. The goal is to produce the fuselage geometry such that it may be used to create molds from which the actual aircraft skins may then be manufactured.

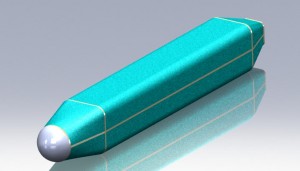

Render of the base plug to be created.

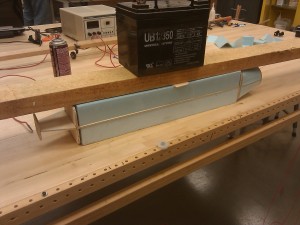

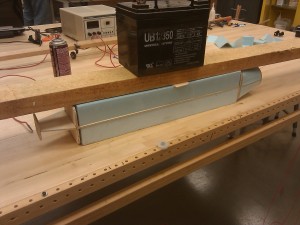

The core of the plug was made using a combination of foam and thin plywood. As shown below, the plywood bulkhead serve to create the profile shape of the body while the lengthwise pieces of plywood serve to keep the bulkheads positioned and aligned correctly. Foam blocks where then glued into the spaces and cut using a hot wire bow and a steady hand. Once cut, the bulkheads are shimmed as needed and the gaps filled with epoxy.

Early stage of plug fabrication

To create the spherical nose of the aircraft, a foam ball from a crafts store was shaved down on a sanding belt until the correct circumference was had. This was then epoxied to the front bulkhead. Once all the foam was in place, the remaining seams and imperfections were covered in spackle and sanded down.

Plug covered in spackel ready for sanding

Next, the wing saddle is cut out of the plug. This wing will sit such that the leading edge and trailing edge will sit flush with the body. The cut is accomplished by clamping a plywood profile of the bottom of the wing to the plug. Clamps, screws, and a plywood offset piece all work to keep the profile in place. Again the cut is completed with a hot wire bow and a steady hand.

Plug ready for wing saddle to be cut

The last remaining feature to be added was the ventilation scope. The basic shaped was cut out of foam using a template and the hot wire bow. This was then glue to the plug. A mix of Capasil and epoxy were then applied along the edge and smoothed with a gloved finger to create a bevel. After curing, Bondo was used to create a smooth transition from the rear of the scoop to the body.

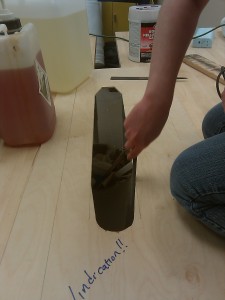

Initial scoop added to plug

With the plug shape complete, the plug was spackeled and sanded several times to get it as smooth as possible. The plug was then fiberglassed and sanded. The fiberglass plug was then touched up with Bono before once again being sanded and then spray painted. A final wet sanding of the painted surface completed the construction of the plug.

Completed fuselage plug