RepRap Mondo – Part 7 – Endstops

- August 10th, 2011

- Write comment

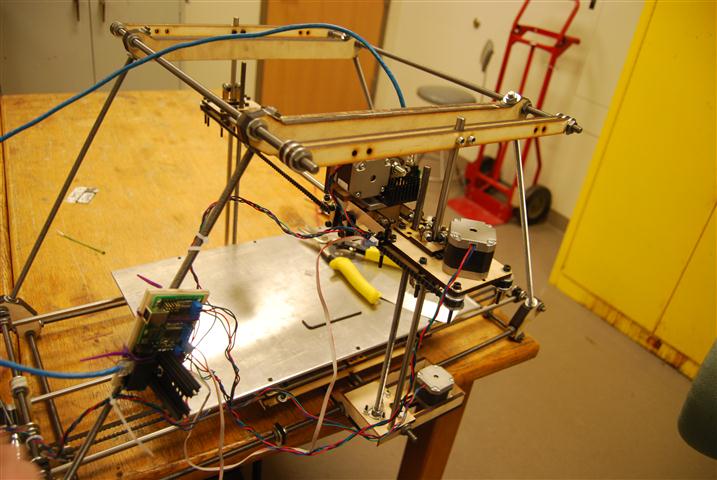

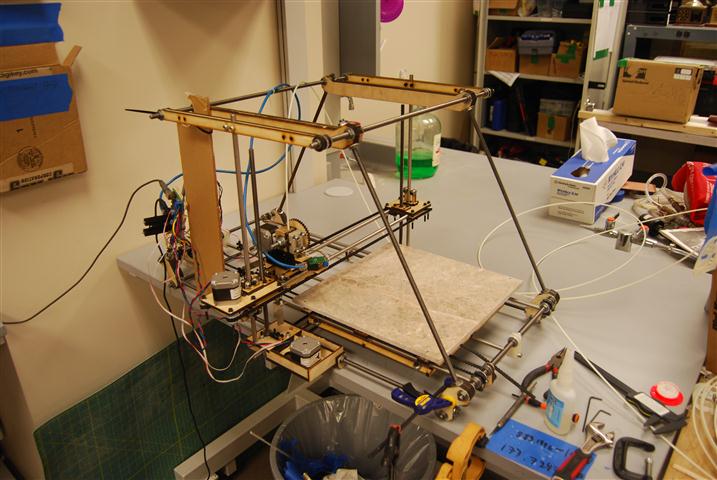

The RepRap Mondo’s mechanics are one of its strongest attributes, however in designing the machine it appears that the endstops were completely forgotten. As a result of this and a complete lack of instructions, the locations and mounts for all the endstops shown are based only on our conjecture, but having run our machine for a while now we can confirm that these positions do work.

The cables that came with the endstops do not fit properly on the pins from the endstop. As a result, they have a tendency to pop off. We cut off the ends an soldered them directly to the contacts inside the end-stops. These were exposed by cutting part of the end-stop enclosure off.

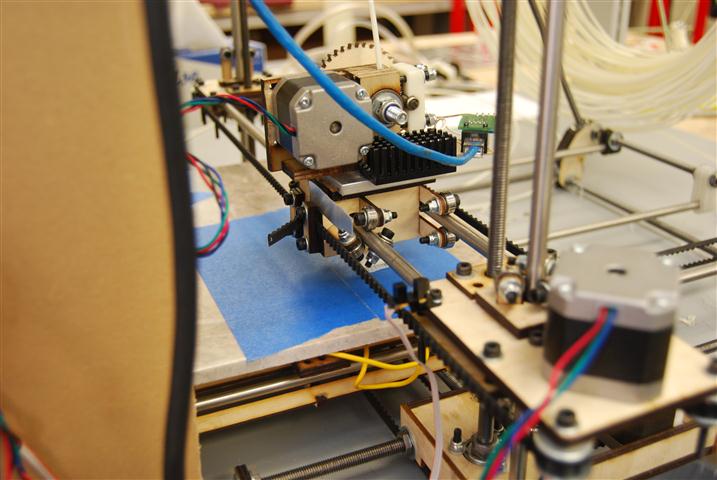

The X-axis end-stop sensor was mounted to an extra hole we conveniently found on the elevator assembly. The kit ships with a piece of thin aluminum that we cut down to the size shown. The belt clamp was loosened and the aluminum plate was slipped in. On tightened down the clamp held the aluminum quite well. There is a small angle cut into the bottom of the aluminum plate so that if it gets bumped down the angle will cause the piece to get pushed back up instead of being mangled.

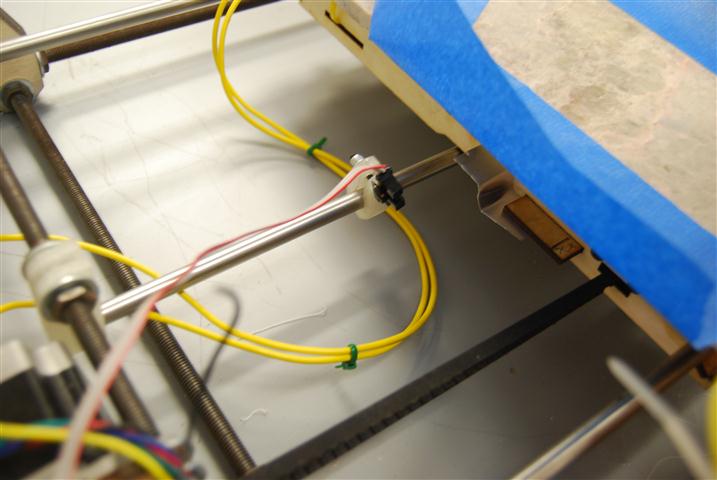

The Y end-stop sensor mounts to a small RepRapped piece which slides over the Y axis smooth rods. A bolt clamps the rod and holds the sensor. A small piece of wood was glued to the bed to make a small shelf to mount the aluminum piece. The Z-bend in the aluminum makes it easier to adjust. The aluminum is super-glued to the bed frame shelf. To clear the deck, the sensor is bent back at a slight angle. It would probably also work to mount the sensor rotated 180 to avoid needing to tilt it.

The Y end-stop sensor is mounted so far forward in the above picture because our marble bed is currently 6 inches shorter than the warped 18″ bed that the kit shipped with.

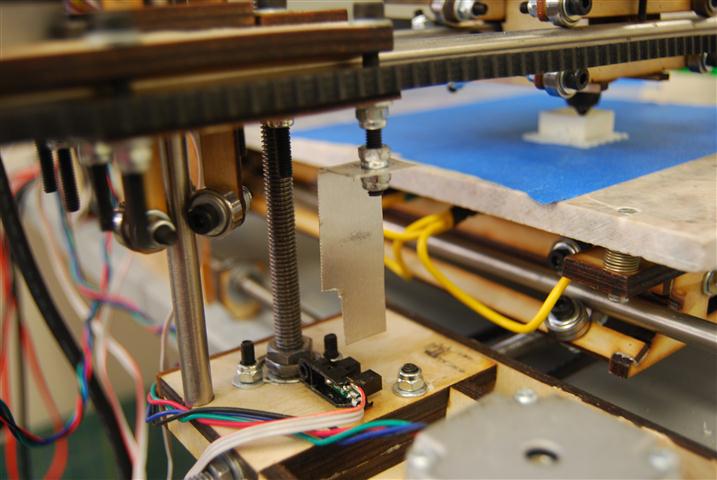

To mount the Z End-stop we glued the sensor on its side to the base of the elevator. We then cut a hole in the aluminum piece and used lock-nuts to attach it to the bottom of one of the screws used int he elevator assembly. This is the only end-stop mount that is finely adjustable and is so specifically because you will need to tune this axis the most. Slight adjustments can make a big difference.