Servo Sin Wave

- May 18th, 2012

- Write comment

Automatic code generation is a powerful tool that when combined with Simulink promises important benefits to students and highly complicated applications alike. Mathworks distributes an Arduino Blockset for Simulink. The Arduino platform is a desirable to use because of its simple architecture and available hardware. These hardware options include the ArdupilotMega (APM) which includes sensors and pinouts that will make it easier to integrate into a future aerial vehicle.

While the 2012a version only requires the base Matlab and Simulink packages, NCSU does not currently provide the 2012a version to students. Instead the 2011a version was used since it was available. It is not expected that there will be problems using the work done with 2011a in the 2012a release.

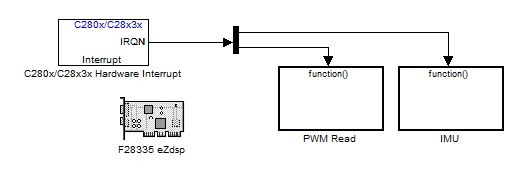

The base Arduino blockset includes blocks for Analog and Digital I/O as well as serial communication. To take full advantage of the capabilites of the APM, additional blocks for SPI, I2C, PPM, and Servos are needed. Development of a servo blocks has been the focus of this last week.

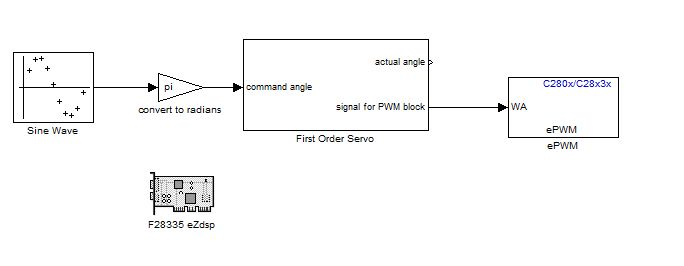

The new blocks, shown in blue, allow for the configuration and control of servos attached to the APM. An interesting note is that although the APM only has 8 servo lines broken out on the side, there are an additional 3 lines (PL3, PB5, and PE3) that can be configured to output PWM commands. These lines are broken out from the APM base-board, but are not available on the sensor-shield “Oilpan”.

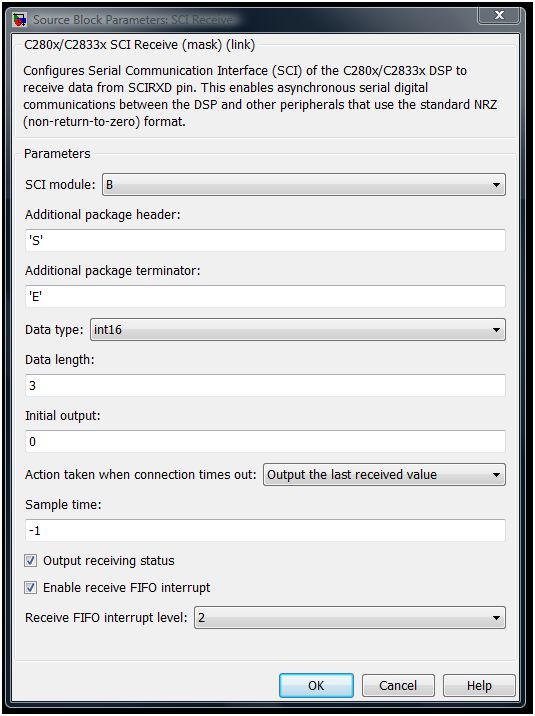

With just the blocks from the base, shown in yellow, and the new servo blocks it is already possible to access quite a few of the APM’s functions. The demonstration program shown above commands two servos through a sin wave motion. Data is read from the serial port allowing for the functionality of Servo 1 to be switched between sin wave and center position.