RepRap Mondo – Part 3 – Frame

- July 15th, 2011

- Write comment

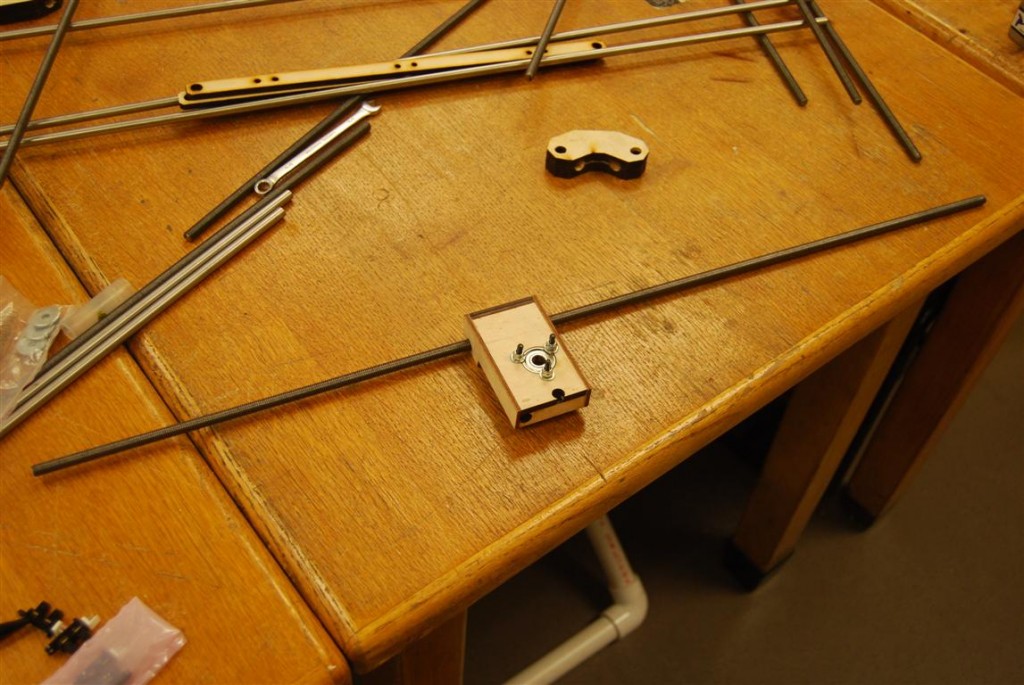

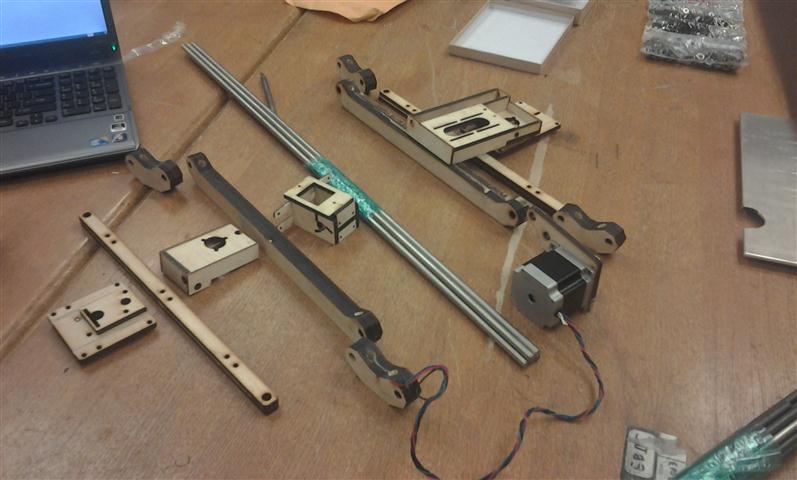

Without instructions, our first task was to identify which rods went where. Once fitted together it becomes clear where the rods go.

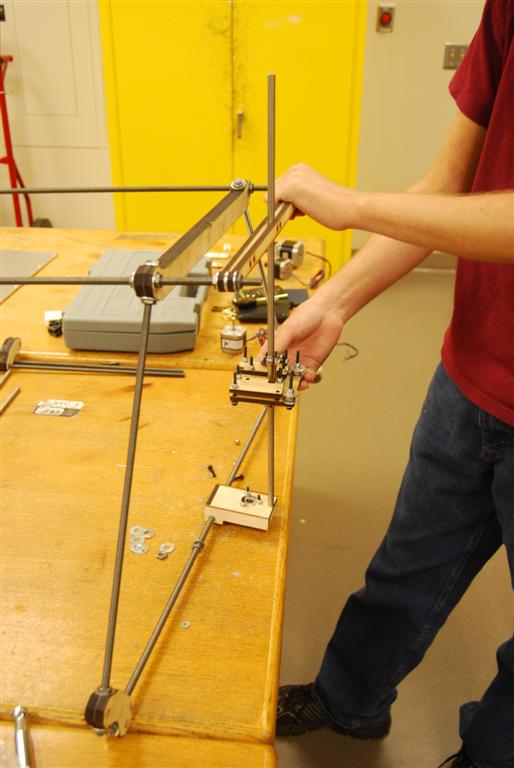

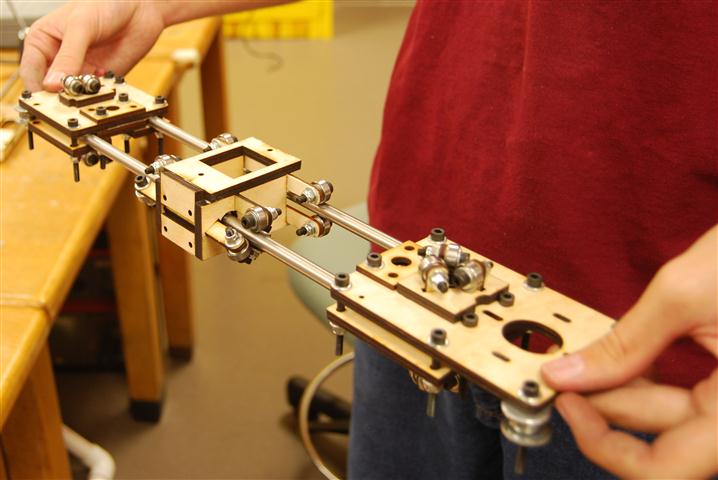

The base mounts for the elevator assembly was then slid on to the long base rod. Wooden feet were then added as well as washers, and nuts to keep them all in place.

After loosely adding washers and nuts to keep the frame from falling apart, the smooth rod for the elevator assembly was slipped between the two outer pieces of wood. The base of the rod was then set into the base and the nuts at the top of the structure were adjusted to keep the rod straight vertical.

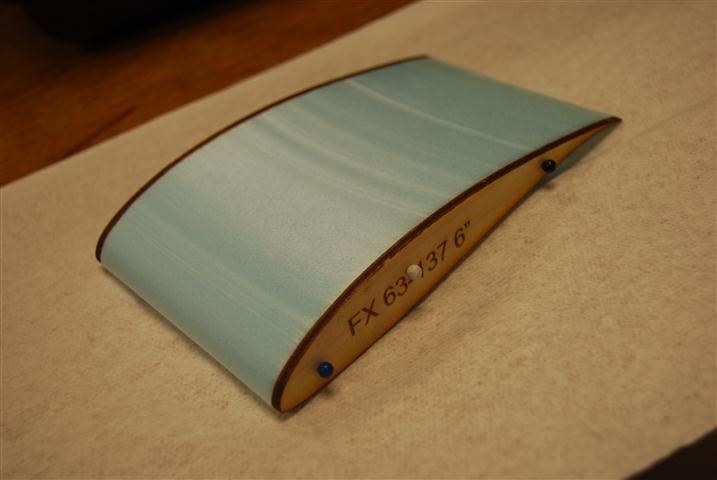

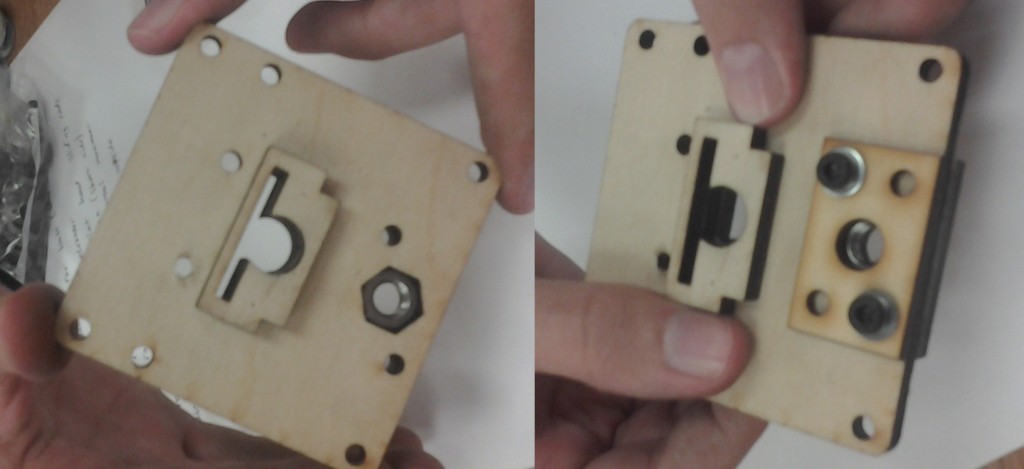

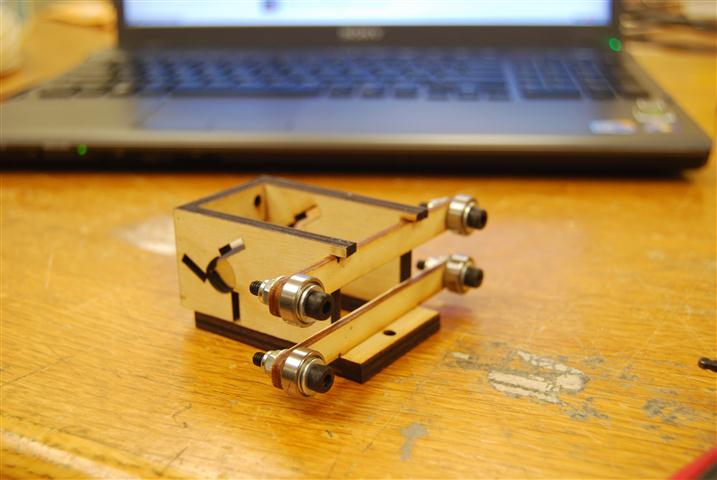

The bed was then prepared by adding roller assemblies to it. These are similar to those used on the elevator assembly. On the side shown there are three pairs of two rollers. On the opposite side there are three pairs of three rollers. In the middle is a single roller which will sit on top of the center smooth rod.

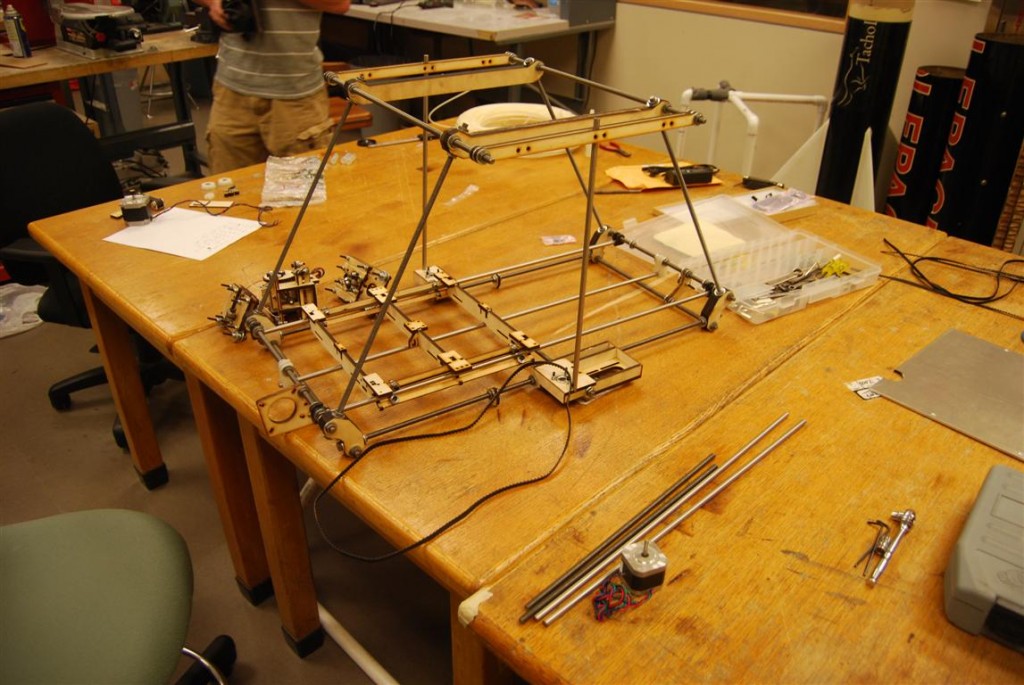

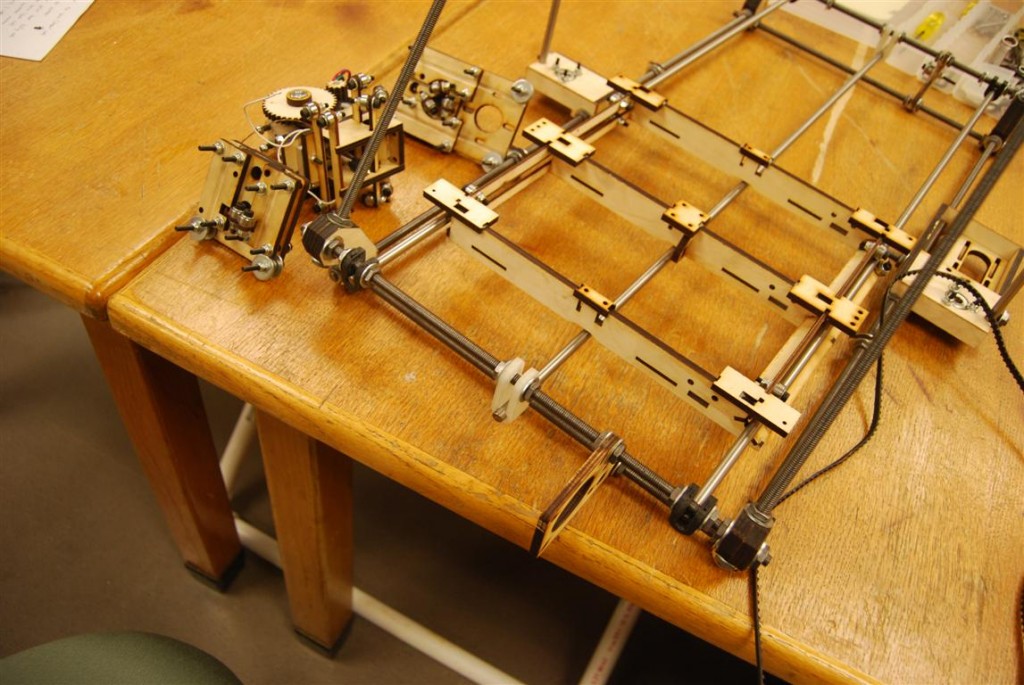

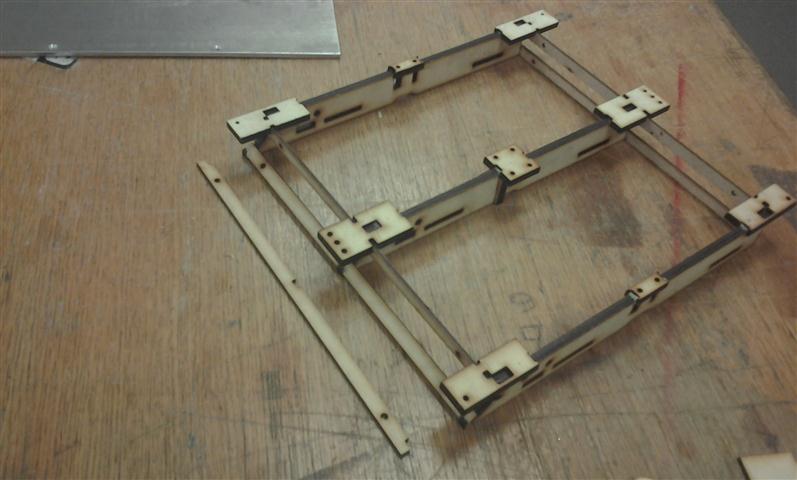

The rods for the bottom of the frame were then slipped together. The goal being to produce the overall assembly shown below.

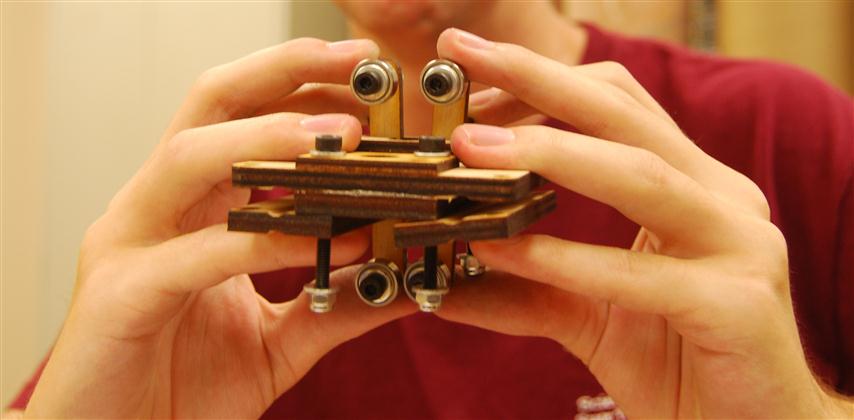

On the motor’s end of the frame, two black rod supports were added on either end. A longer white support was put in the middle and the motor mount to its right.

On the other side is a similar assembly, but with a roller bracket support in place of the motor.

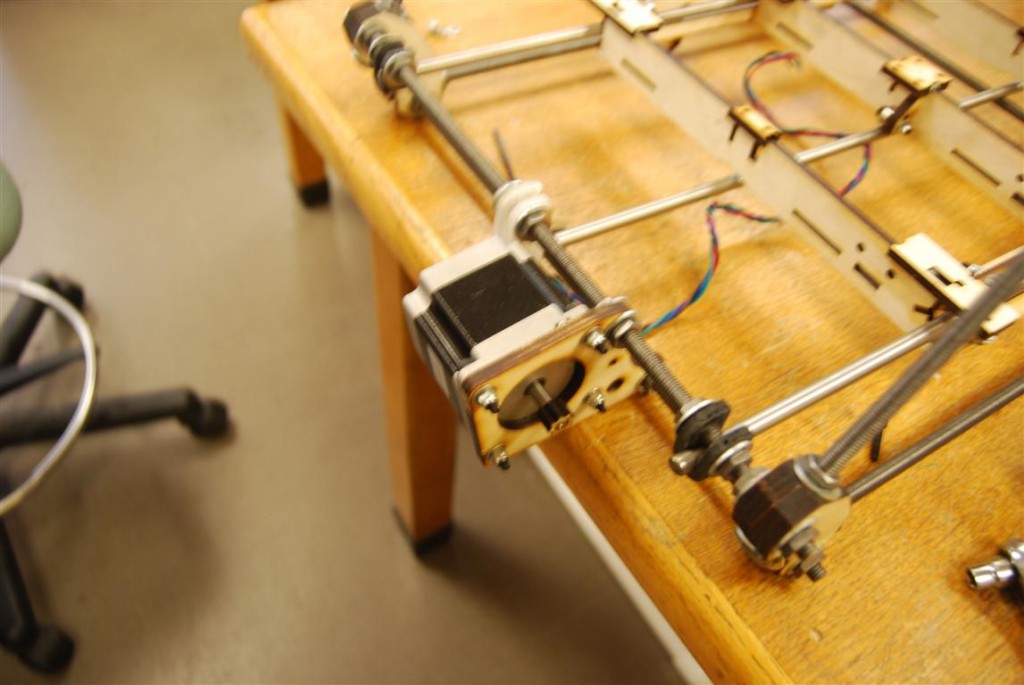

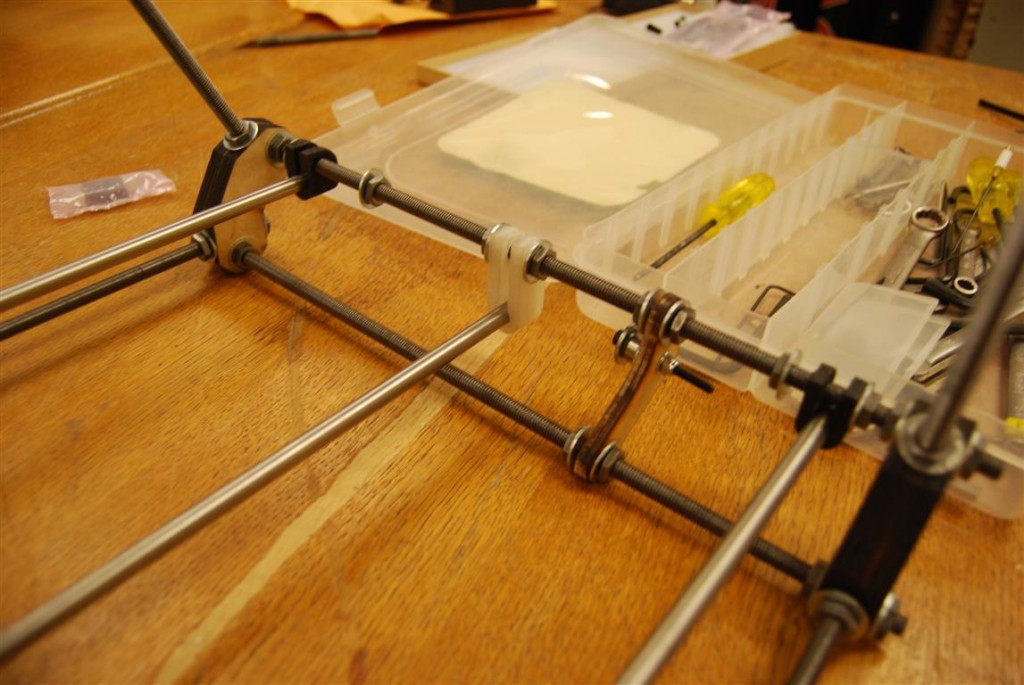

Closer up you can see the multitude of nuts and washers needed to keep everything in its place. You can also see how the belt will be positioned later on.

Once everything was loose fitted, the rod with three rollers on it was slid out and the bed installed. Once the outer frame was squared and leveled, the rod with three rollers was aligned a specific distance from the outer bracket. The other rod supports were then shifted as needed so that they ran straight under their respective rollers.